| Size | 1220*2440mm/1220*2800mm/1220*3000mm, 4*8ft/4*9ft/4*10ft |

| Grade | E0, E1(German production line) |

| Thickness | 6-25mm |

| Certification | CE / ISO9001 / FSC / CARB |

| Usage | Furniture, Wardrobe, doors, Office file cabinet, decoration |

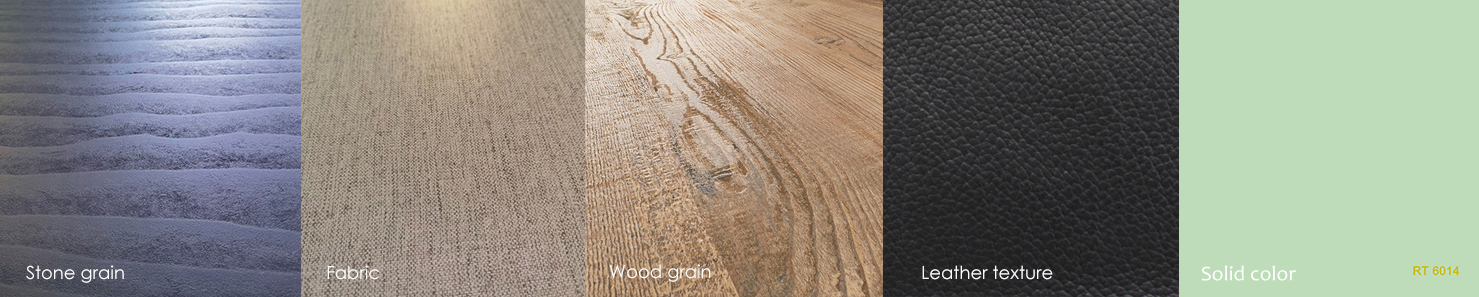

| Color | Solid color, wood grain, stone grain, fabric, leather texture |

| NO | SANDED&UNSANDED MELAMINE PARTICLE BOARD |

UNIT | STANDARD VALUE | RESULT |

| 1 | In-board density deviation | % | ±10.0 | -3.0, +1.5 |

| 2 | Moisture content | % | 3.0~13.0 | 15.9 |

| 3 | Static bending strength | MPa | ≥11.0 | 13.5 |

| 4 | Elastic Modulus | MPa | ≥1600 | 2946.00 |

| 5 | Internal bonding strength | MPa | ≥0.35 | 0.45 |

| 6 | 2h Water absorption thickness expansion rate | % | ≤8.0 | 2.0 |

| 7 | Surface bond strength | MPa | ≥0.8 | 1.25 |

| 8 | Thickness | Mm | +/- 0.8 | +/- 0.5 |

| 9 | Length | Mm | +/- 0.3 | +/- 0.2 |

| 10 | Width | Mm | +/- 0.3 | +/- 0.2 |

| 11 | Squareness tolerance | Mm/m | 2 | +/- 0.2 |

| 12 | Formaldehyde emission | mg/m3 | E1≤0.124 | 0.044 |