What is synchronized board?

Synchronous melamine board is a type of engineered wood product that is commonly used in the construction and furniture industries. It is made by compressing wood fibers or particles together under high pressure and heat, resulting in a dense and durable board with consistent density throughout.

Synchronous melamine board is a type of engineered wood product that is commonly used in the construction and furniture industries. It is made by compressing wood fibers or particles together under high pressure and heat, resulting in a dense and durable board with consistent density throughout.

The term "synchronous" refers to the fact that the density of the board is synchronized or uniform across its entire surface. This is achieved through a professional manufacturing process that ensures the fibers or particles are evenly distributed and compacted to a consistent thickness.

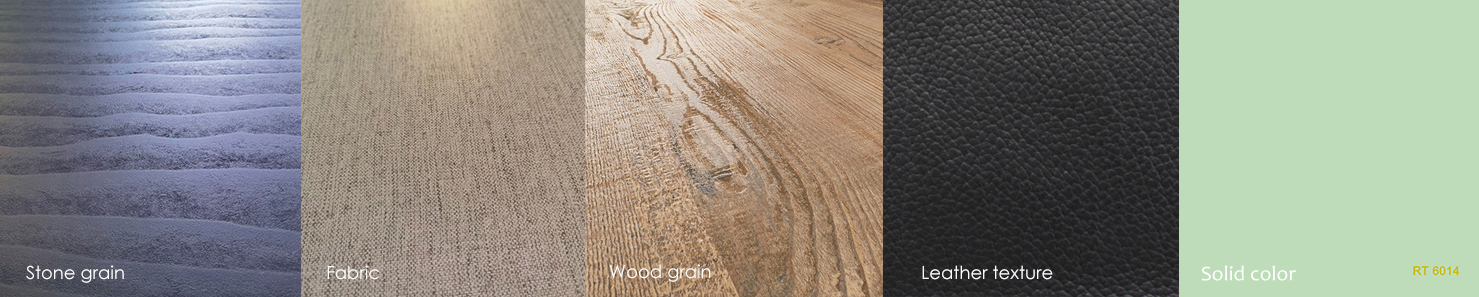

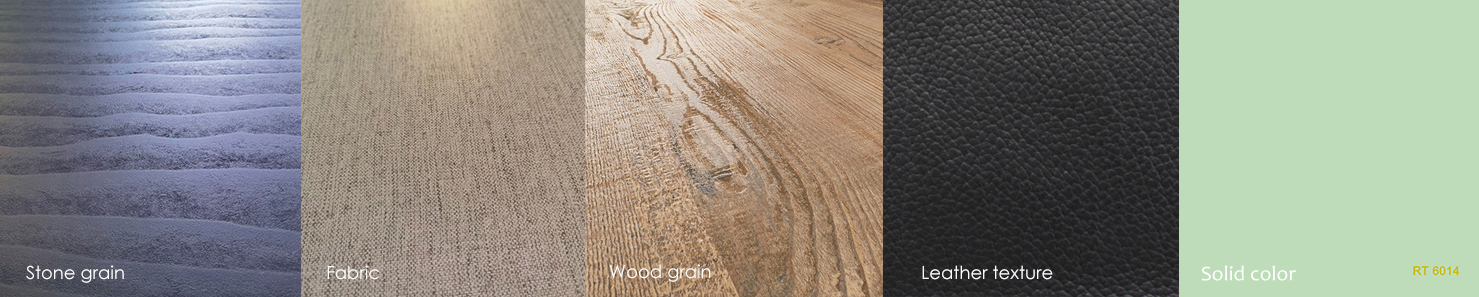

DARA WOOD synchronized designs combine the best quality paper, match with top-notch steel template, template texture totally agree with paper texture to make the surface not only looks like woodgrain, but also touches and feels like natural grain.

We have 200+ synchronized designs, include, wood grain, fabric, stone grain, leather texture and more.

Product Details

| Size |

1220*2440mm/1220*2800mm/1220*3000mm, 4*8ft/4*9ft/4*10ft |

| Grade |

E0, E1(German production line) |

| Thickness |

6-25mm |

| Certification |

CE / ISO9001 / FSC / CARB |

| Usage |

Furniture, Wardrobe, doors, Office file cabinet, decoration |

| Color |

Solid color, wood grain, stone grain, fabric, leather texture |

1. Our Advantages:

1) 200+ synchronized designs

2) Support customized

3) 12 production line

4) 17 patents

5) Technial support

6) Professional R&D team

2. Test Report: for technical data sheet, please contact us

| NO |

SANDED&UNSANDED

MELAMINE PARTICLE BOARD |

UNIT |

STANDARD VALUE |

RESULT |

| 1 |

In-board density deviation |

% |

±10.0 |

-3.0, +1.5 |

| 2 |

Moisture content |

% |

3.0~13.0 |

15.9 |

| 3 |

Static bending strength |

MPa |

≥11.0 |

13.5 |

| 4 |

Elastic Modulus |

MPa |

≥1600 |

2946.00 |

| 5 |

Internal bonding strength |

MPa |

≥0.35 |

0.45 |

| 6 |

2h Water absorption thickness expansion rate |

% |

≤8.0 |

2.0 |

| 7 |

Surface bond strength |

MPa |

≥0.8 |

1.25 |

| 8 |

Thickness |

Mm |

+/- 0.8 |

+/- 0.5 |

| 9 |

Length |

Mm |

+/- 0.3 |

+/- 0.2 |

| 10 |

Width |

Mm |

+/- 0.3 |

+/- 0.2 |

| 11 |

Squareness tolerance |

Mm/m |

2 |

+/- 0.2 |

| 12 |

Formaldehyde emission |

mg/m3 |

E1≤0.124 |

0.044 |

3. Application

4. Other product

Synchronous melamine board is a type of engineered wood product that is commonly used in the construction and furniture industries. It is made by compressing wood fibers or particles together under high pressure and heat, resulting in a dense and durable board with consistent density throughout.

Synchronous melamine board is a type of engineered wood product that is commonly used in the construction and furniture industries. It is made by compressing wood fibers or particles together under high pressure and heat, resulting in a dense and durable board with consistent density throughout.